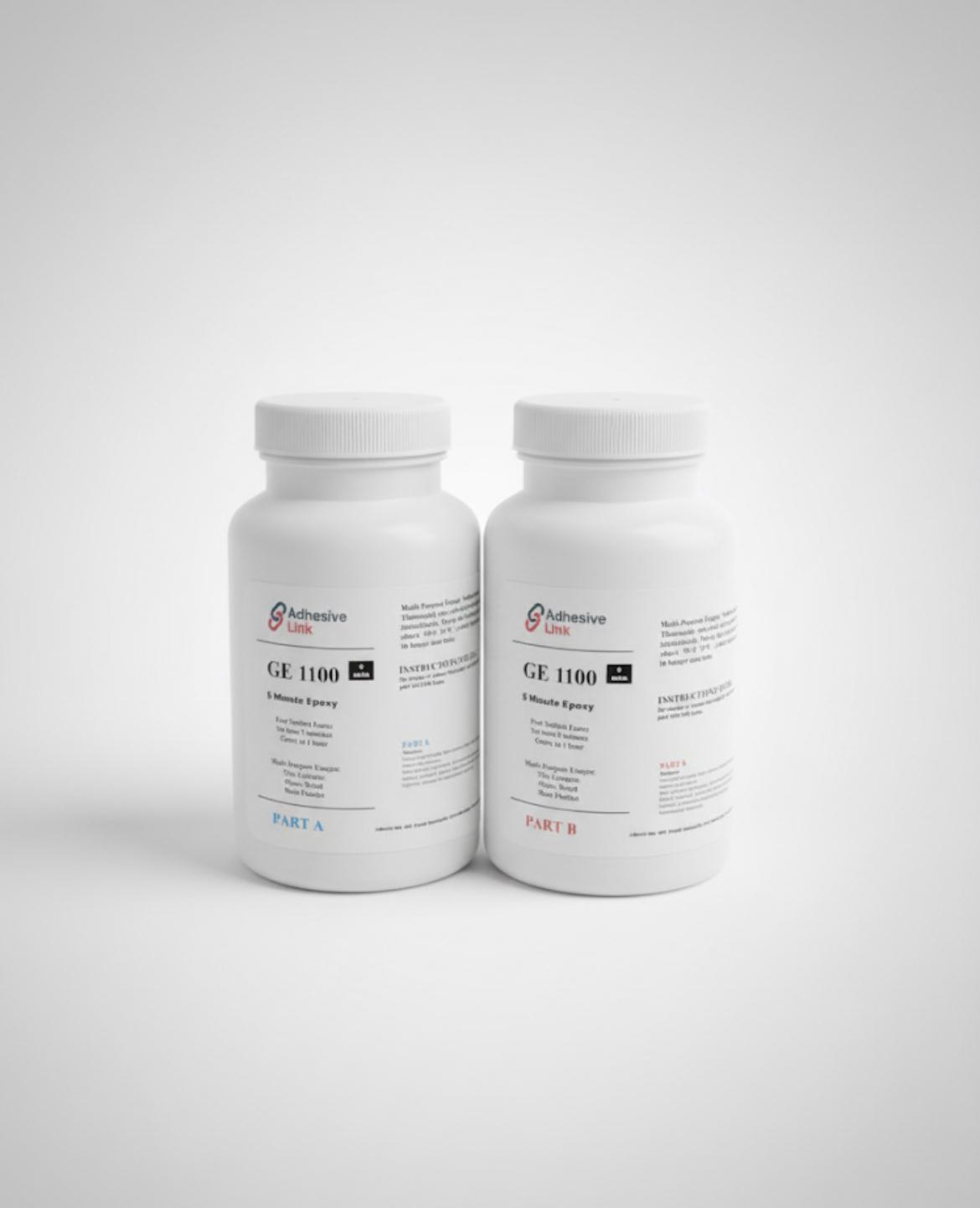

Epoxy adhesives are strong, versatile, two-part structural glues used for bonding various materials like wood, metal, glass, and ceramics. Key factors for successful use include proper mixing, appropriate temperature, and adequate curing time.

Common Epoxy Adhesive FAQs

Q: What is the correct way to mix epoxy?

A: Most epoxy systems are two-part (resin and hardener) and require a precise mixing ratio specified by the manufacturer.

A: Most epoxy systems are two-part (resin and hardener) and require a precise mixing ratio specified by the manufacturer.

- Combine the two parts in a clean container, and mix thoroughly for 1-2 minutes, scraping the sides and bottom. For larger projects, it is often best to mix smaller batches to avoid the mixture heating up and curing too quickly (exotherm).

- Ensure there are no streaks or striations, as incomplete mixing is a common cause of curing problems.

Q: Why is my epoxy still sticky or tacky?

A: The most common reason for sticky or uncured epoxy is an inaccurate mix ratio or insufficient mixing.

A: The most common reason for sticky or uncured epoxy is an inaccurate mix ratio or insufficient mixing.

- Other causes can be applying the epoxy in conditions that are too cold or humid.

- To fix this, scrape off the soft, uncured material, clean the surface with a solvent (like denatured alcohol), and apply a fresh, properly mixed batch.

Q: What materials does epoxy not bond well to?

A: Epoxy generally bonds well to most common surfaces such as wood, metal, glass, and ceramic. However, it does not stick well to certain plastics, including:

A: Epoxy generally bonds well to most common surfaces such as wood, metal, glass, and ceramic. However, it does not stick well to certain plastics, including:

- Silicone

- Polyethylene (HDPE)

- Polypropylene (PP)

- Teflon (PTFE)

- Wax paper or parchment paper

Q: Are safety precautions necessary when using epoxy?

A: Yes, safety precautions are essential. Uncured resin and hardener can cause skin and eye irritation, and repeated contact can lead to allergic sensitization over time.

A: Yes, safety precautions are essential. Uncured resin and hardener can cause skin and eye irritation, and repeated contact can lead to allergic sensitization over time.

- Work in a well-ventilated area.

- Wear personal protective equipment (PPE), including nitrile gloves, safety goggles, and a NIOSH-approved respirator with an organic vapor cartridge if necessary.

- If skin contact occurs, wash immediately with soap and cool water.

Q: Can I use epoxy for outdoor projects?

A: Most epoxies are not naturally UV stable and may yellow or chalk over time when exposed to direct sunlight. For outdoor use, it is recommended to protect the epoxy with a UV-resistant coating, such as a marine-grade polyurethane varnish.

A: Most epoxies are not naturally UV stable and may yellow or chalk over time when exposed to direct sunlight. For outdoor use, it is recommended to protect the epoxy with a UV-resistant coating, such as a marine-grade polyurethane varnish.

Q: How should I store epoxy adhesive?

A: Store the resin and hardener in tightly sealed original containers in a cool, dry place away from direct sunlight, ideally between 60°F and 80°F. Proper storage helps maximize the shelf life, which is typically one year or longer if stored correctly.

A: Store the resin and hardener in tightly sealed original containers in a cool, dry place away from direct sunlight, ideally between 60°F and 80°F. Proper storage helps maximize the shelf life, which is typically one year or longer if stored correctly.

The most common epoxy mistakes in resin art involve inaccurate measuring and mixing, failing to control the working temperature, and inadequate workspace preparation. These errors often lead to frustrating issues such as the resin remaining sticky, developing bubbles, or having a cloudy finish.

Top Common Mistakes and How to Avoid Them

Inaccurate Measuring & Mixing: This is the number one cause of failed resin projects. The resin and hardener require a precise ratio to cure correctly.

-

- Avoid: Never "eyeball" the measurements. Use a measuring cup with clear lines or a digital scale (depending on whether the product specifies measurement by volume or weight). Mix slowly but thoroughly for at least 3 to 5 minutes, scraping the sides and bottom of the container to ensure all components are fully integrated.

- Ignoring Environmental Factors (Temperature and Humidity): The ideal working environment for most epoxies is a warm, dry room, typically between 70°F and 80°F (21°C–26°C).

- Avoid: Avoid working in cold or high-humidity conditions, as this can make the resin thick, lead to cloudiness, or prevent proper curing. Warm the sealed resin and hardener bottles in a warm water bath before use if they are too cold.

- Trapped Air Bubbles: Bubbles naturally form during the mixing and pouring processes.

- Avoid: Stir the mixture slowly to minimize introducing excess air. After pouring, use a heat gun or a small flame torch (held a few inches away and kept moving) to gently pop surface bubbles. For deep pours, use a casting resin designed for thicker layers or pour in multiple thin layers, allowing each to partially cure first.

- Unclean Workspace/Dust Contamination: Dust, pet hair, or other particles can easily land in the wet resin and cure into the finished piece.

- Avoid: Work in a clean, dust-free area. Cover your project with a cardboard box or plastic container while it cures to protect it from airborne contaminants.

- Adding Too Much Colorant or Incompatible Additives: Adding excessive pigment, especially water-based dyes, can interfere with the chemical reaction and prevent the resin from curing properly.

- Avoid: Use colorants specifically designed for epoxy resin. A general guideline is to use no more than 6% colorant to the total volume of resin and hardener. Always conduct a small test batch first when trying new colorants.

- Rushing the Curing Process: Patience is crucial. Not allowing enough time for the resin to fully cure can result in a soft or tacky finish.

- Avoid: Follow the manufacturer's specified cure times (which can be several days for a full cure) and resist the urge to touch the piece while it's curing.